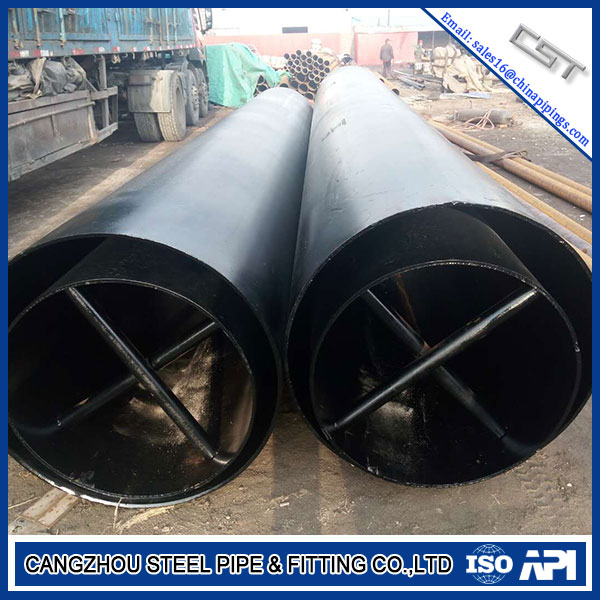

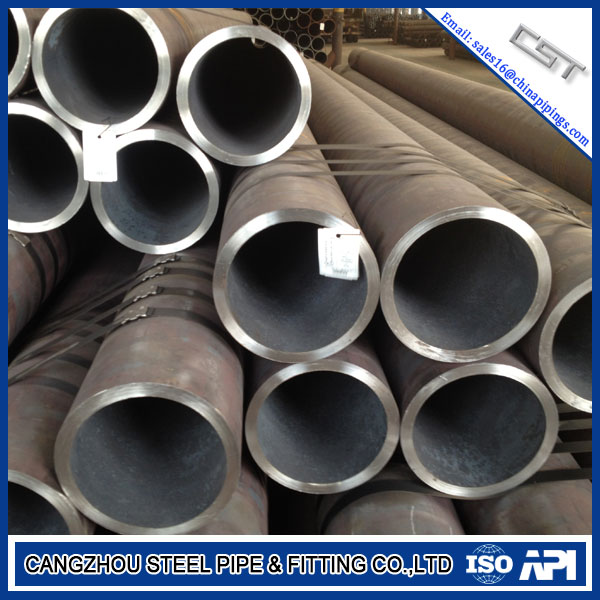

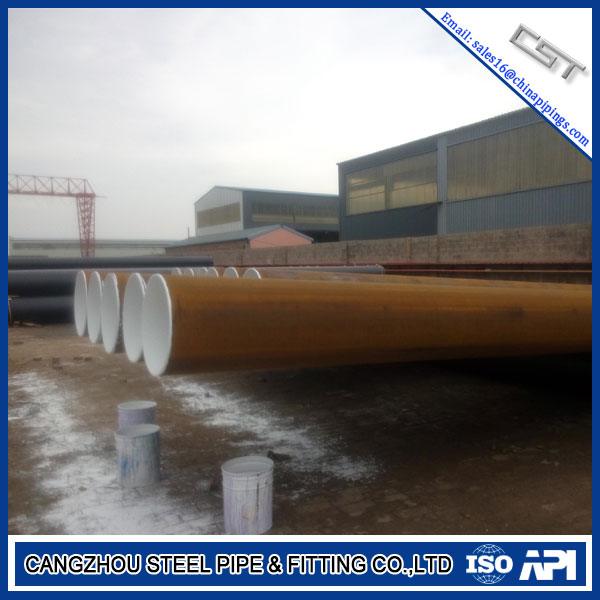

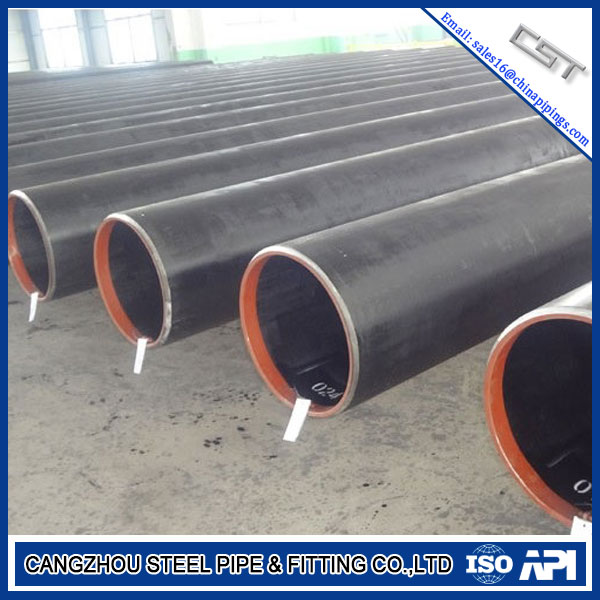

Manufacturing process of spiral welded pipes

Spiral welded pipe,as the name implies,is a kind of steel pipe with a spiral form seam running its entire length. In the past,spiral welded pipe was relegated to low pressure and structural applications for the method of their manufacture.With the development of the submerged arc welding process, the production of large

hot rolled coils of sufficient width and the development of dependable non-destructive testing methods, it is now able to produce spiral weld pipe for high-pressure service.

Manufacturing process of spiral welded pipes:

1. Raw materials are strip coils, welding wires and fluxes. Strict physical and chemical testing is required before input.

2. The steel head and tail are butt jointed,and the single wire or double wire submerged arc welding is used.After the steel pipe is rolled into a steel pipe,automatic submerged arc welding is used for repair welding.

3. Before forming,the strip is leveled,trimmed,planed,surface cleaned and treated.

4. The electric contact pressure gauge is used to control the pressure of the cylinder on both sides of the conveyor to ensure the smooth conveying of the strip.

5. Using external control or internal control roll molding.

6. The weld gap control device is used to ensure that the weld gap meets the welding requirements,and the pipe diameter,the amount of misalignment and the weld gap are strictly controlled.

7. Both internal and external welding are carried out by American Lincoln welding machine for single or double wire submerged arc welding to obtain stable welding specifications.

8. The welded welds are inspected by online continuous ultrasonic automatic injury inspection to ensure the non-destructive testing coverage of 100% spiral welds.If there is a defect,the alarm is automatically alarmed and sprayed, and the production worker adjusts the process parameters at any time to eliminate defects in time.

9. Cut the steel pipe into a single root using an air plasma cutting machine.

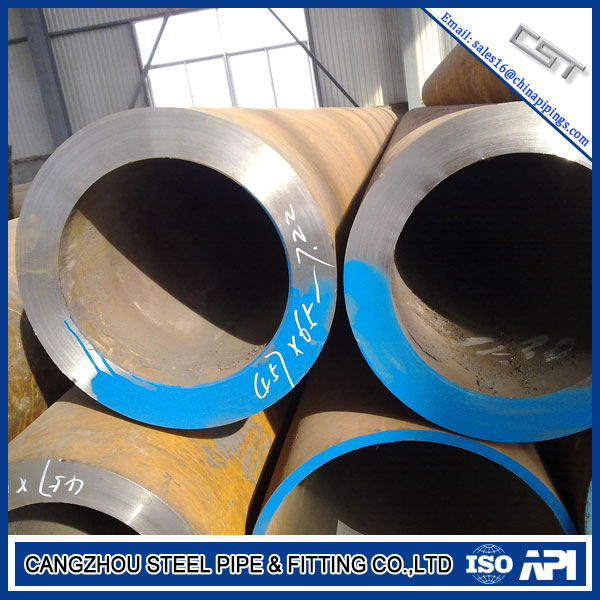

10. After cutting into a single steel pipe, the first three inspections of each batch of steel pipe shall be subjected to a strict first inspection system to check the mechanical properties,chemical composition,fusion condition,surface quality of the steel pipe and non-destructive testing to ensure the pipe production process.After that,it can be officially put into production.

11. The part of the weld with continuous sound wave detection mark, after manual ultrasonic and X-ray review,if it is defective, after repairing,it will pass the non-destructive test again until it is confirmed that the defect has been eliminated.

12. The tube of the butt weld of the strip and the joint of the butt joint intersecting the spiral weld are all inspected by X-ray TV or film.

13. Each steel pipe is subjected to hydrostatic pressure test and the pressure is sealed by radial.The test pressure and time are strictly controlled by the steel pipe water pressure microcomputer detection device.Test parameters are automatically printed and recorded.

14. The pipe end machining, so that the verticality of the end face,the groove angle and the blunt edge are accurately controlled.

CST manufacture high quality spiral welded pipes with international standards or as customer required.The steel pipes raw materials can be ASTM A106 Gr.B,ASTM A53 Gr.B,ASTM A312 TP304-TP316-TP321-TP347,ASTM A333 Gr.3-Gr.6,ASTM A335 P1-P5-P9-P11-P22,API 5L Gr.B-X42-X52-X56-X60-X65-X70,API 5CT J55-K55-N80-R95-M65-L80-C90-T95-C110-P110-Q125,etc.If you want to know more about our products,please email us:sales@haihaogroup.com