Wall thickness deviation of seamless steel pipe

We, Cangzhou Steel Pipe & Fitting Co. Ltd. , export all kinds of seamless steel pipes all over the world. But there is one problem of seamless steel pipes, it’s wall thickness deviation.

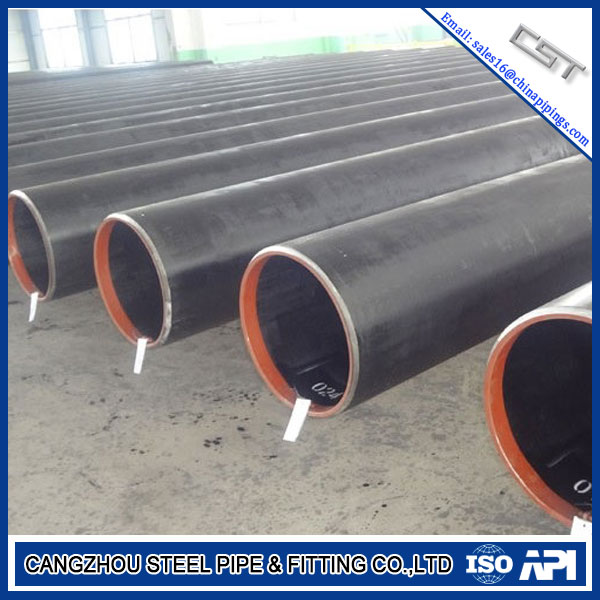

The most common defects for seamless steel pipe is uneven wall thickness. Seamless steel pipe wall thickness deviation performance reason:

Since puncher in the head with a perforated plunger between the first support frame centering rollers cantilever structure is formed, so that the head during piercing irregular beating, so the head will be uneven force within the tube, causing the wall thickness deviation generated.

Manufacturing precision equipment and structures:

Since the stablity of the perforator roll and the guide plate is poor, so that the device generates a large jump in the perforation, the impact of the tube thickness of the device manufacture; old structure and centering rolls on the roller and is generally due to the lower roller is not an institution drive, so the centering rollers, its center at the time of the actual installation and adjustment, the theory is not easy to pinpoint the center generated when the plunger hold three centering rollers, so that will result in the perforated top radial centering rollers hold the rod being produced uneven stress, poor stability, causing the wall to produce deviations.

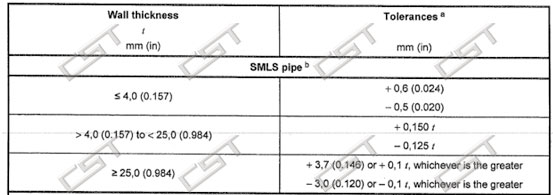

From the above, uneven wall thickness of seamless steel pipe is inevitable. But our company will control the quality seriously according the standard of seamless steel pipes. Here is the wall thickness tolerance of seamless steel pipes.