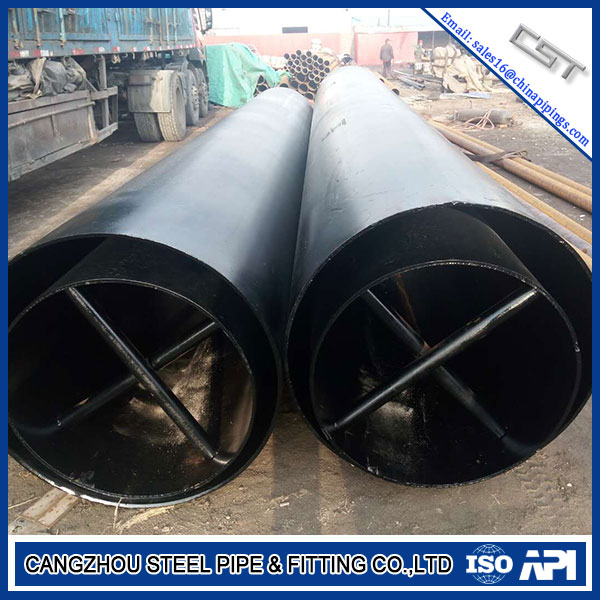

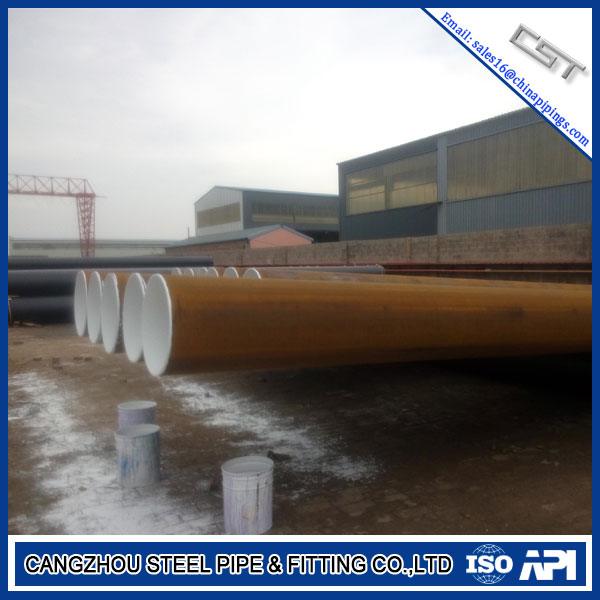

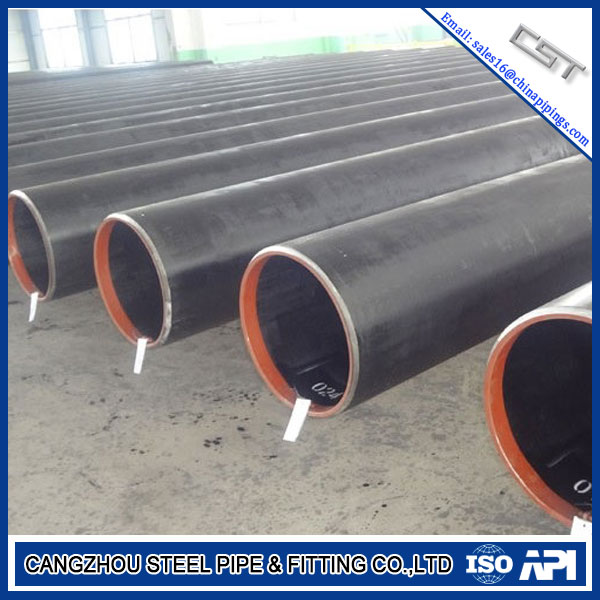

Cement Lined

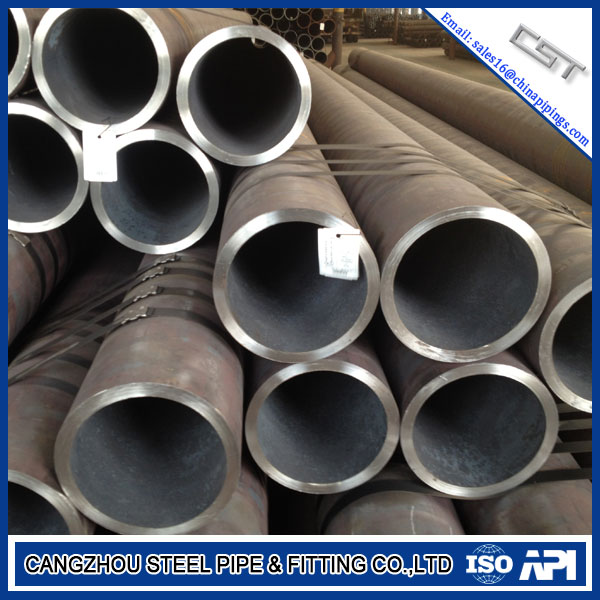

Cement lining is a process by which steel pipe and fittings are coated internally with cement mortar. This process combines the physical strength of steel with the protective qualities of cement mortar. The lining is applied centrifugally to pipe, creating a smooth finish in the length of the pipe, Fittings, flanges, and special spool pieces are lined by hand. With our stock of domestic or import material, we offer quick turnarounds, competitive pricing and an experienced, professional staff that can handle any request.

Interal cement lining is usually applied to prevent internal corrosion of carbon steel cooling water or fire-fighting water piping systems containing sea-water or brackish water at ambient temperatures. Alternatives to cement lined carbon steel piping for sea-water or brackish water service are glass-reinforced epoxy (GRE) piping, concrete piping or epoxy coated/lined piping, their selection depending on local/process conditions and life-cycle costs.

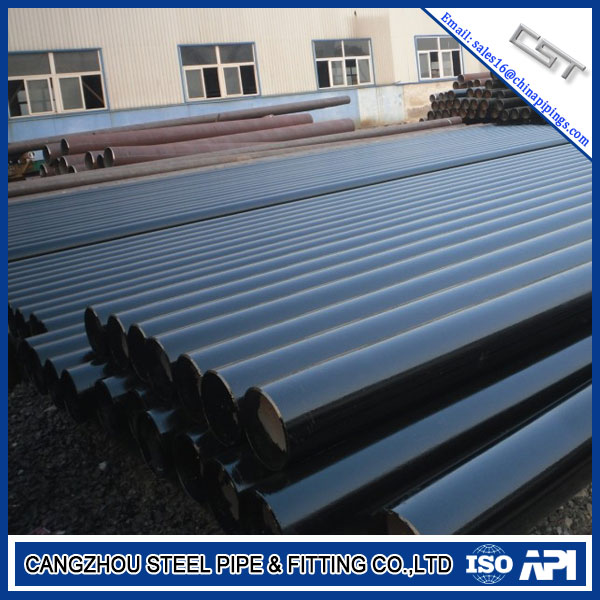

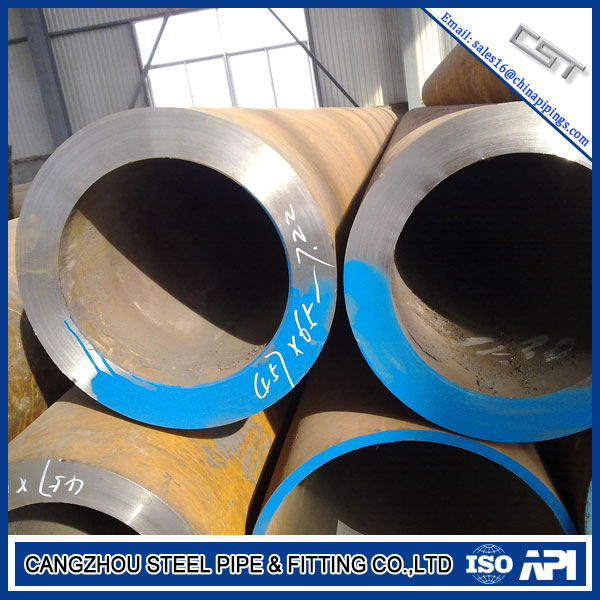

Straight sections of pipes,diameters from DN100 up to and including DN900, length 6m to 13m, shall be lined by spinning method. The interior surface shall be smooth, straight and true and the sand/cement particles shall be equally distibuted throughout the lining thickness, after completion of the lining process. Bends and fittings which cannot be machine lined in accordance with spinning method may receive a hand-applied mortar lining. Hand-applied mortar shall have a uniform surface. Cement mortar for hand work shall be of the same consistency and materials as the mortar for machine method. Surface to be lined shall be cleaned in accordance with (4.1,surface preparation: The inside of the pipe shall be cleaned of all grease,mill scale,loose rust or other foreign materials,by blast cleaning to at least Sa2,or by power tool cleaning to St3, in accordance with ISO 8501-1.) and damped with water immediately prior to placing the hand-applied motar. Steel finishing trowels shall be used for hand application of cement mortar.