Cement lining production for pipe fittings

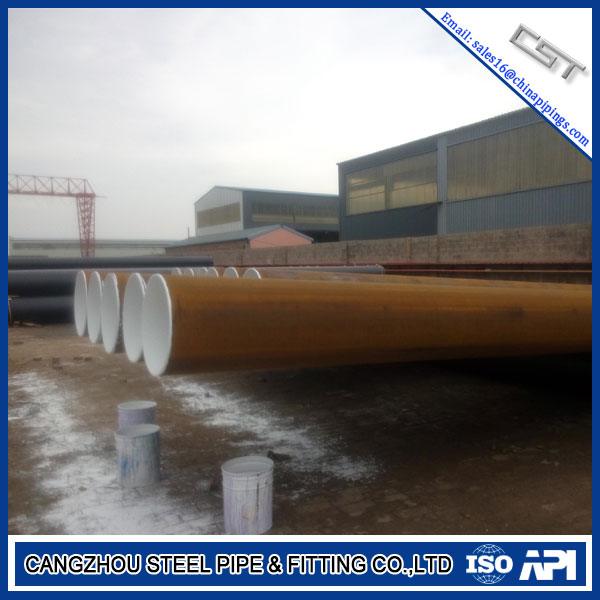

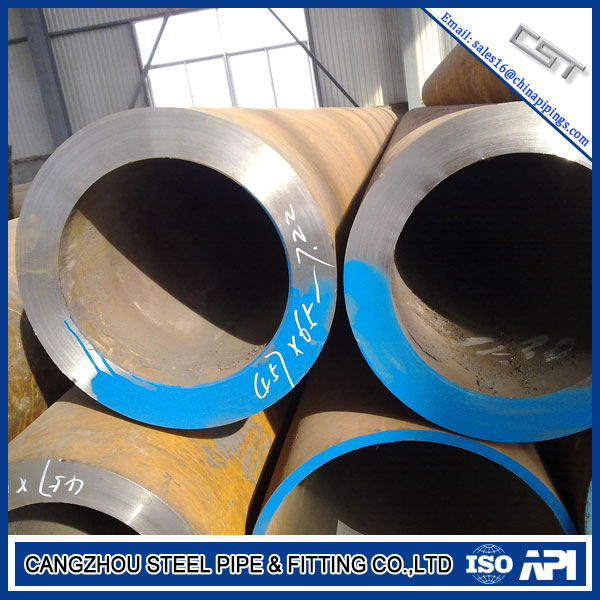

Make the cement mortar mixture,then put the mixture on the cleaning of the pipe wall thickness according to the design requirement,put once time or twice lining.After a certain time after curing,form a closely combined to pipe wall high strength round shell lining layer above average diameter of large diameter pipe corrosion of cement mortar to join the barbed wire in order to enhance robustness of the cement mortar,fall off to prevent the cracks.

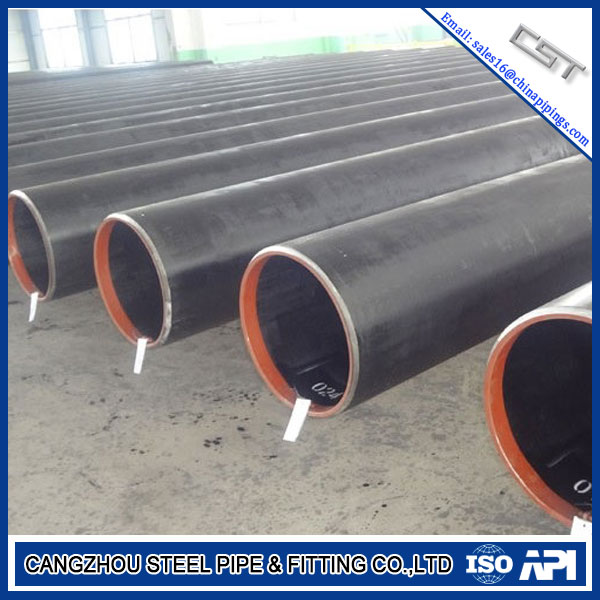

The passivation film formed on the inner surface of the pipe is protected by using the special alkaline of cement mortar.

One is centrifugal,the other is spray.

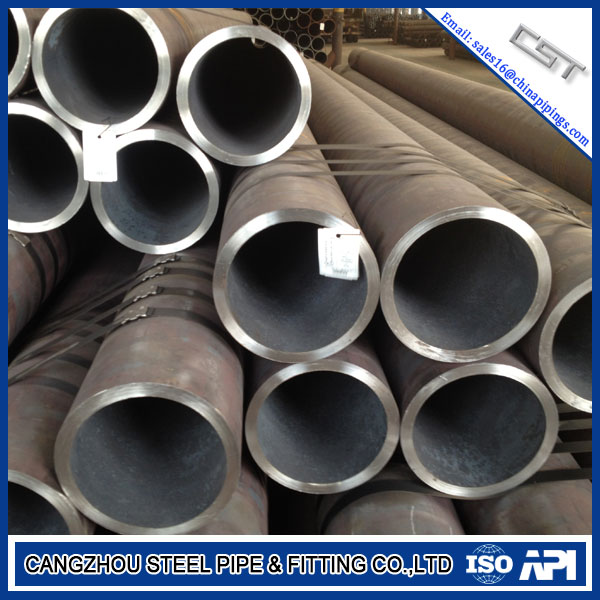

Centrifugal method refers to the construction process of using centrifuge and other equipment to make cement mortar rotate at high speed with steel tube,producing large centrifugal force, so as to uniformly adhere to the inner wall of steel tube.Generally, it is applicable to anti-corrosion construction in pipeline in small size pipe.

Spraying method refers to the construction process of applying cement mortar to the inside of steel pipe by spraying machine,which is generally applicable to large size pipeline anti corrosion construction.

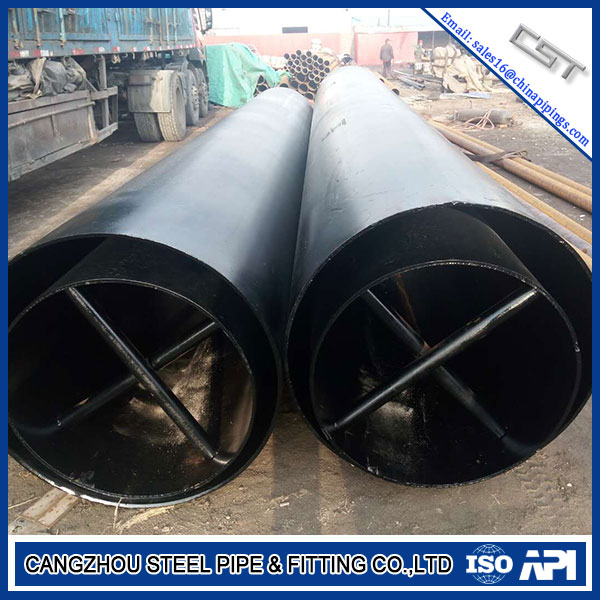

At present, the cement lining of large-size pipe fittings is only completed by manual operation,usually by spraying or manual operation.Generally,the wire is welded through the inner wall of the pipe fitting and the adhesion is increased.Then,the cement mortar is manually applied.