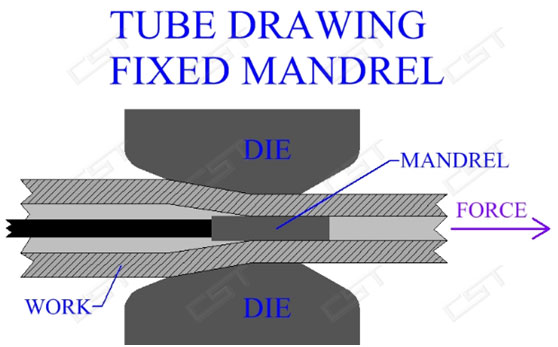

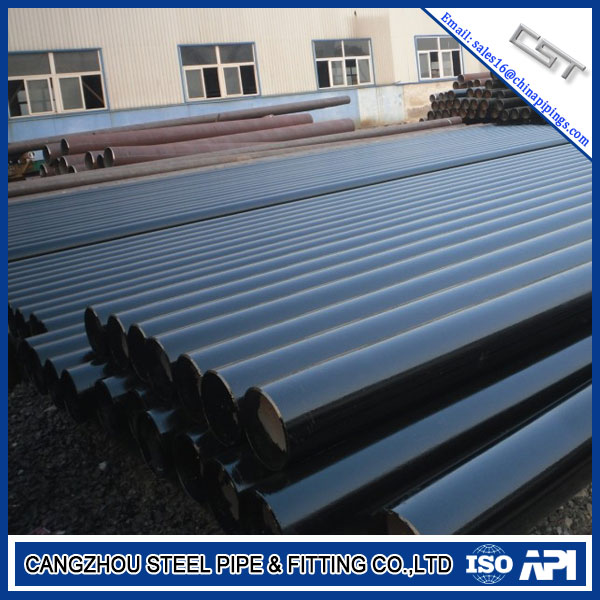

Cold drawing for seamless steel pipes

The Definition

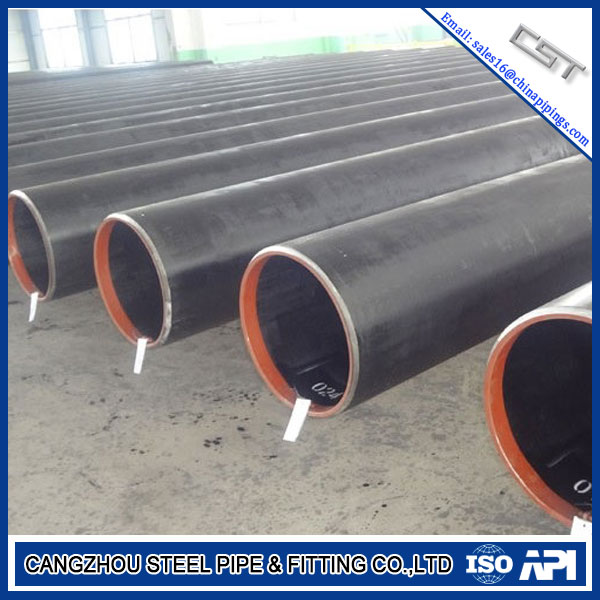

Cold drawing steel pipe is a kind of steel pipe,it is classified according to different production processes, which is different from hot rolling (expansion) pipe.Cold drawing steel pipe includes general steel pipe,low and medium pressure boiler steel pipe,high pressure boiler steel pipe,alloy steel pipe,stainless steel pipe,petroleum cracking pipe,mechanical processing pipe,thick wall pipe,small diameter plus inner mold cold drawn pipe,it also includes carbon thin-walled steel pipes,alloy thin-walled steel pipes,stainless thin-walled steel pipes,and special-shaped steel pipes.Cold drawn steel pipe can have an outer diameter of 6mm and a wall thickness of 0.25mm. The outer diameter of the thin-walled pipe can be up to 5mm and the wall thickness is less than 0.25mm.The precision and surface quality are obviously better than the hot-rolled (expanded) pipe,but the manufacturing process is restricted,its caliber and length are subject to certain restrictions.

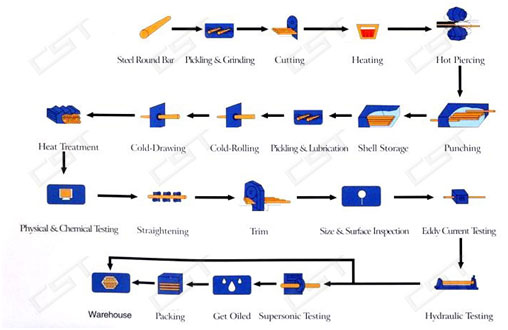

The Manufacturing Process of Cold Drawing Pipes

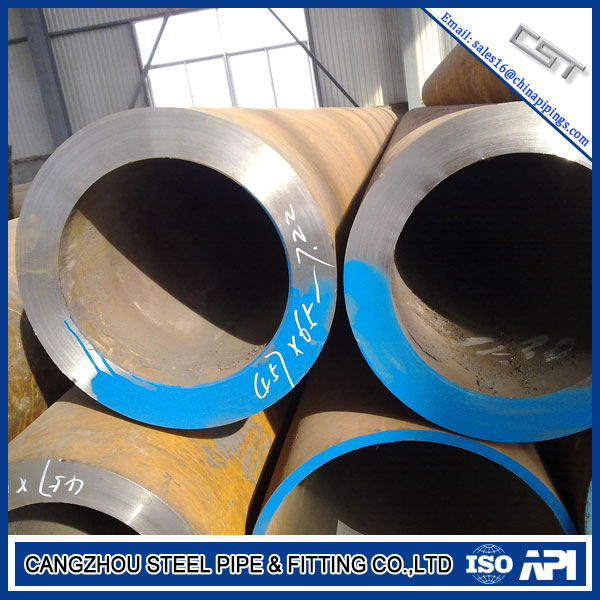

The Usage

Cold drawing steel pipes are precise cold drawing seamless pipes for mechanical structures,hydraulic equipment,with high dimensional accuracy and smooth surface.The use of precision seamless pipes to manufacture mechanical structures or hydraulic equipment can greatly reduce machining time,improve material utilization,at the same time,it can help to improve products quality.