Seamless Steel Pipe Manufacturing Process-Pickling & Phosphating

After heated and hot piercing,seamless steel pipes will be done pickling and phosphating.Pickling is necessary working procedure before phosphating,aim to remove rust and mill scale,which is widely used for the industry.

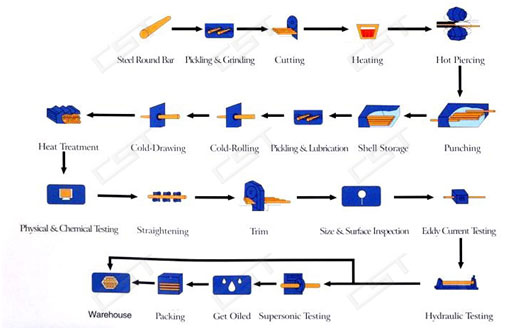

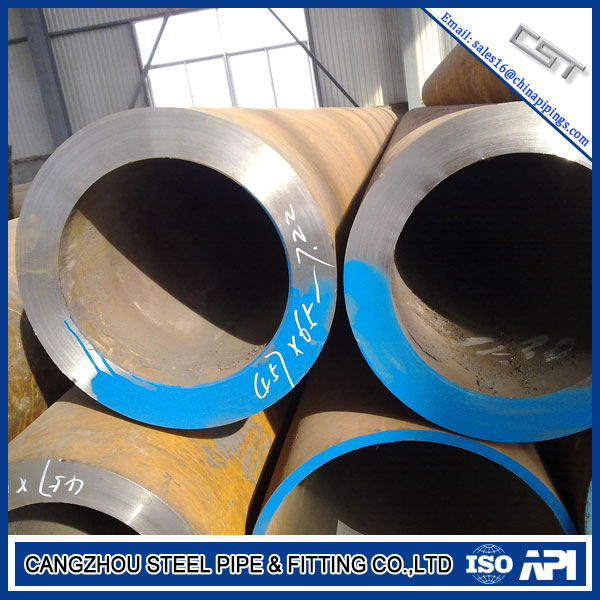

Here is the flow chart of cold drawing seamless steel pipe.

And phosphating of metals is the process of converting a steel surface to iron phosphate,which is one of the most important surface treatment methods and a number of modern metal finishing procedures would not be possible without it.This is mostly used as a pretreatment method in conjunction with another method of corrosion protection.Phosphating is also known as phosphate conversion coatings,which are usually applied to carbon steel,low-alloy steel and cast iron.

The phosphating is normally divided into the following stages,

- Degreasing and cleaning

- Derusting and descaling

- Activation

- Phosphating

The main areas of application of phosphating are:

Corrosion protection in conjunction with organic coatings,such as paints.

Facilitation of cold-forming processes,such as wire drawing and tube drawing,or deep drawing.

Corrosion protection in conjunction with oils and waxes.

Corrosion protection with no subsequent treatment.

During the seamless steel pipe manufacturing process,pickling and phosphating are essential,which prepare for next steps.