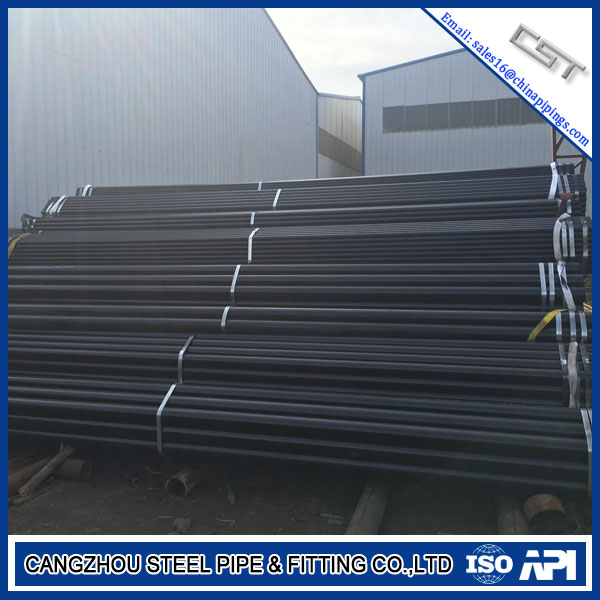

Hot rolling and cold rolling for steel pipes

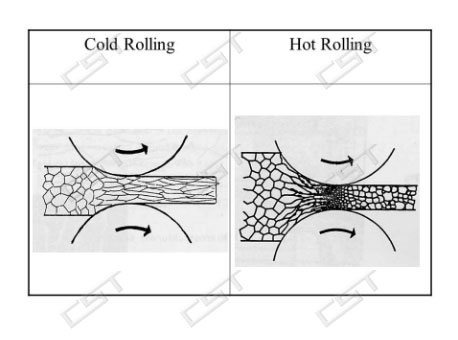

During the production of steel pipes,steel is molded and reshaped with different machinery at different temperatures.One of the steel manufacturing processes is steel rolling.Rolling produces flat steel sheets of a specific thickness,and the process is classified according to the temperature at which the metal is rolled.If the temperature of the metal is above its re-crystallization temperature,or the temperature at which the grain structure of the metal can be altered,the process is termed as hot rolling.If the temperature of the metal is below its re-crystallization temperature,the process is termed as cold rolling.

From the definition,steel ingot or billet is difficult to deform at room temperature,generally heated to 1100~1250℃ and rolled,it’s called hot rolling. Most steel are rolled through this method.But because the surface of steel is easy to make mill scale at high temperature,which brings rough surface of rolled steel and major size fluctuation,it requires another kind of steel, with smooth surface,accurate size and good mechanical property,which can be produced through cold rolling,taking rolled semi-finished or finished products as raw materials.Rolling at room temperature is treated as cold rolling.The boundary of cold rolling and hot rolling is distinguished by re-crystallization temperature.The re-crystallization temperature of steels is 450~600℃.

From the characteristics,hot rolling can reduce energy consumption and cost.The metal has high in plasticity during hot rolling and low deformation resistance,which greatly reduces the energy consumption of metal deformation.And hot rolling can improve the processing performance of metals.But cold rolling without anneal has high hardness and bad mechanical property,only can do bending process less than 90 degree.Simply speaking,cold rolling is based on hot rolling sheet.The process is hot rolling→pickling→cold rolling.