Production technology of finned tubes

As a heat exchanger element,the finned tube works for a long time under high temperature flue gas conditions.For example,the finned tube used for the boiler heat exchanger has a harsh environment,high temperature and high pressure,and is in a corrosive atmosphere,which requires high performance index of the finned tube,as follows,

- 1) Anti-corrosion

- 2) Anti-wear

- 3) Lower contact resistance

- 4) High Stability

- 5) Anti-ashing ability

High perfomance is inseparable from avanced production technology.Usually there are five kinds of production technologies, such as set of fins,mosaic spiral fins,brazed spiral finned tube,high frequency welding spiral finned tube,three-roller cross-rolling integral spiral finned tube,among them,high frequency welding spiral fins are the most widely used.

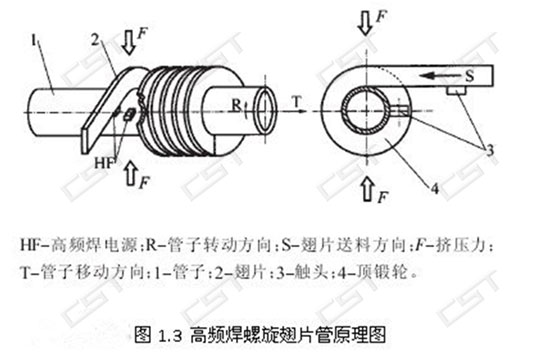

High frequency welding spiral finned tube is manufactured like this.While steel tape is winding steel tube,heat steel tape and the surface of steel tube through skin effect and proximity effect of high frequancy electric current,until plastic status or melt,finish welding under certain pressure of winding steel tape.This high frequency welding is actually a solid phase welding.Comparing with other kinds of production technologies,whether it’s product quality (high weld rate of fins, up to 95%),or productivity and automation,it is more advanced.

The principle of high frequency welding spiral finned tube